Experiments with earth/cob/clay to create egg shape objects continues. Our greenhouse is very cold in the winter at night, lettuce seedlings grow very slowly and humidity is too high (molds grow in the soil). A cob stove could keep the greenhouse warmer during the night as the hot earth releases heat and remove some of the excess humidity, the egg shape may perhaps be more efficient for these purposes, thanks to the way air circulates inside the shape. Clay is an abundant resourse here, I took buckets of earth and mixed it with water and EM using the drill to mix well, filtered twice, first through a large mesh sieve and the second time with a much finer mesh so only the dissolved clay remains. Let it settle for a day or two, remove excess water. With recycled textiles I made a cotton bag to hold the clay and let it drip until dense enough to work with.

The mold used is made of cardboard sections to make up two halves of the egg, divided at the widest circumference, using the ‘colombino’ technique and filling in the gaps with thin rolled up clay, let dry. When the shapes were hard enough to be moved without distortion, I placed one half on a base made of clay and a cylindrical piece of marble found in the woods (?!).

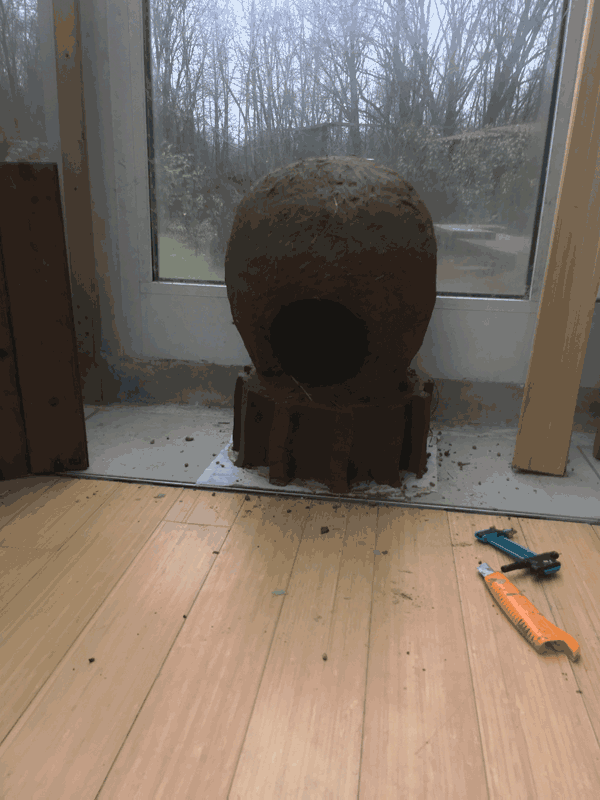

The last pictures show the work of thickening the walls so they retain the most heat possible, this layer of clay is mixed with hay for strength, the last finishing layer will be clay only. The mouth of the stove will be a circle carved towards the bottom of the shape.

After finishing the last layer, I started a fire inside the shape to accelerate the drying process and test it. The result was a whole lot of smoke (I was unable to keep a flame burning due to continuous movement of air inside and the fact the the shape had only one opening) and the collapse of the shape due to the softness of clay which was still too wet.

Hahahahaha! Wonderful! I started all over again, this time following the example of the rocket stove/mass heater…

Update 18.01.21

The stove dried and I tried firing, still too much smoke to be able to heat the greenhouse without opening doors and therefore letting heat out, this prototype does not have a mass large enough to store a lot of heat. I read the book: Rocket Mass Heaters Edition III © 2014 Ianto Evans and Leslie Jackson. Wonderful resourse. I understand that if firewood is to be used to heat the greenhouse the stove needs much better combustion, exhaust pipe and much larger mass.

I’m reflecting upon the adequacy of this solution and the amount of work it will require, wether I’m able to still use the structure made and if/how to adapt it.

In the meantime I’m playing around with greenhouse plans and I’m experimenting with making cob bricks, this way I am able to work a few hours a day, digging up clay one bucket at a time and eventually build the stove in one or two days. In this regard it is important for the reader to know that most of my day is dedicated to daily tasks such as food preparation, feeding the stove that heats our home in the winter, wood collecting, fermentation, cleaning tasks and other daily maintanance, following up on homeschooling, etc. Time dedicated to extraordinary maintanance is limited to a couple of hours a day, perhaps even four when I’m lucky. So the need to dose the time dedicated to this big task becomes evident.